| Topic: Universal polishing attachments for lathes | |

| Date Issued: November 24, 2023 | Date Revised: |

A certified machinist had their hand torn off while operating a lathe machine. The worker was polishing a steel shaft by hand using a piece of emery cloth. Their left hand was pulled into the lathe machine by the spinning shaft. The worker was transported to hospital where it was later determined that their left arm would require partial amputation.

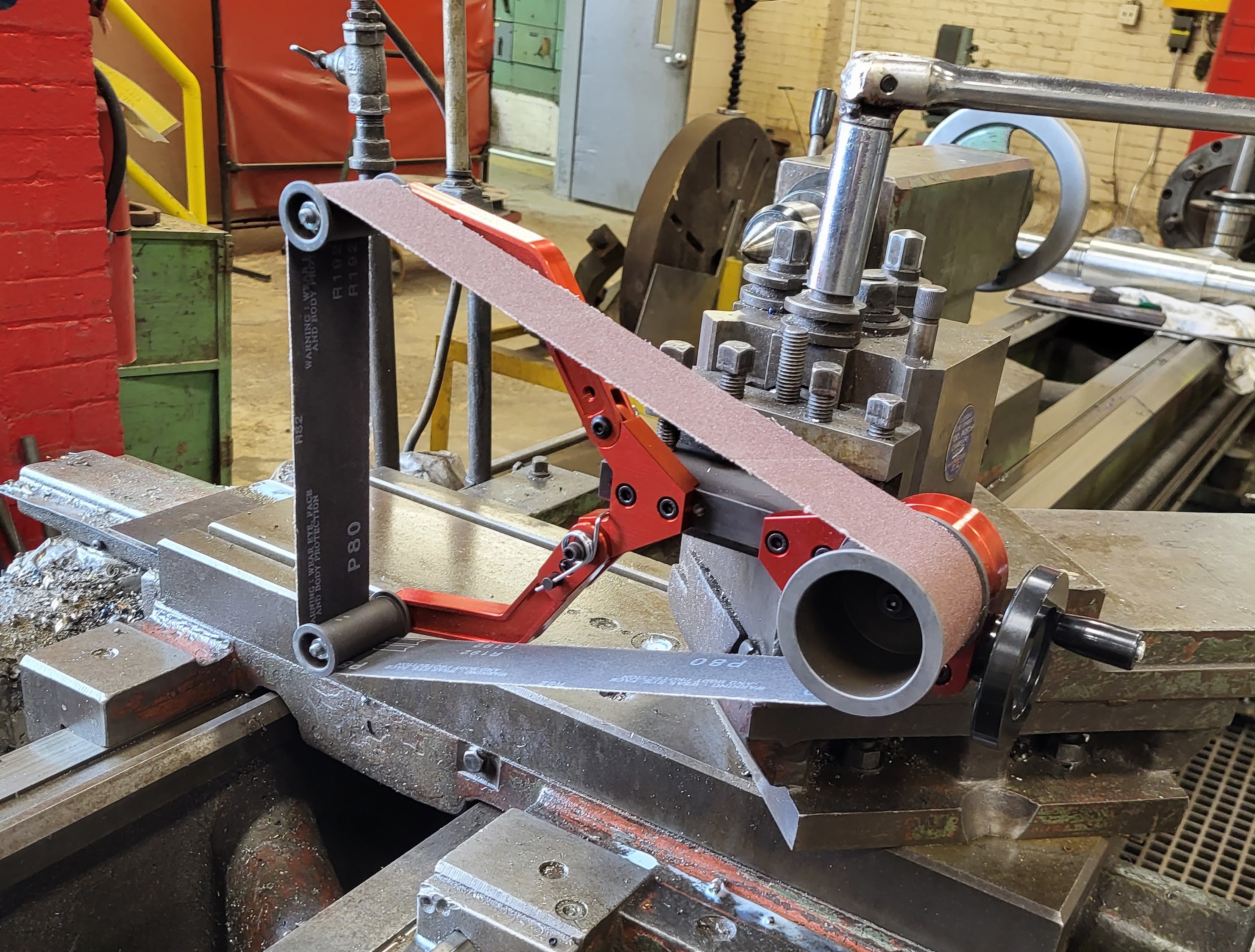

It’s common in the machining industry to polish materials by hand. Universal polishing attachments for lathes are available commercially and offer protection from the moving parts of the machine.

Section 242 of General Regulation 91-191 requires employers to provide adequate safeguards to prevent employees from contacting moving parts on a machine. If a safeguard cannot be provided, the employer must make a physical modification to the machine or prepare a written safe work procedure.

The following websites provide examples of safe work procedures. They should be adapted to the lathe being used and work being done.

Ontario Ministry of Labour Alert: Machine Shop Lathes