| Topic: Battery Explosion Injures Worker | |

| Date Issued: July 1, 2004 | Date Revised: |

In cold weather, powered mobile equipment batteries are especially prone to discharge due to frequent idling and many starts and stops. When a battery charge drops below 12.4 volts, the acid (60%) and water (40%) mixture, known as an electrolyte, in the battery separates. The battery acid then reacts with lead plates inside the battery, creating a highly explosive hydrogen gas. As pressure inside the battery increases, the gas is vented to the outside through ventilation openings. In cold weather, the water can also freeze and expand, placing pressure on the battery.

This leads to three possible explanations:

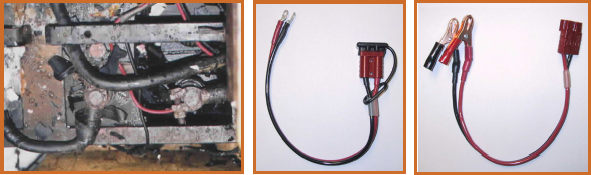

Sparks are common when placing and removing booster cables and can provide the ignition that would begin the reaction leading to an explosion.

Revised November 2014